flow rate calculator 3d printer

Measure near the center of the cube not near the edges. Using the Ender 3s control interface go to Control Motion E-stepsmm.

Ad Photon M3 Anycubic 3D Allows You to Print Almost Anything for Your Creative Projects.

. Wanhao i3 Plus Whirligig cooler glass bed. How to calibrate the 3D printer before an extruder change. Formula to calculate the necessary flow for any material.

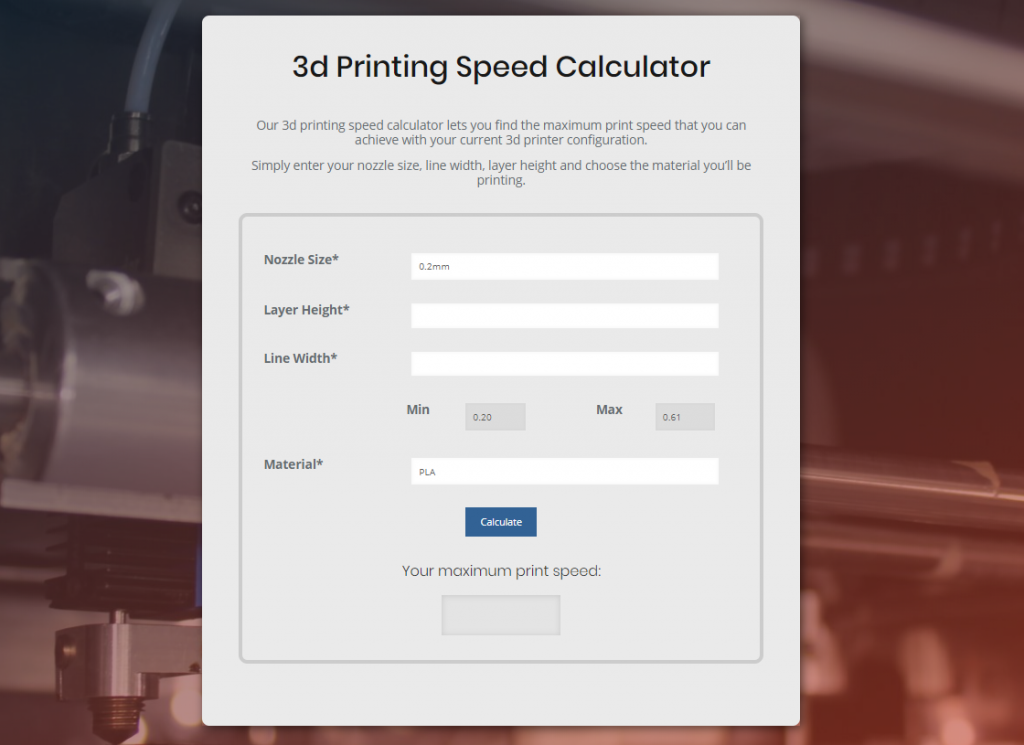

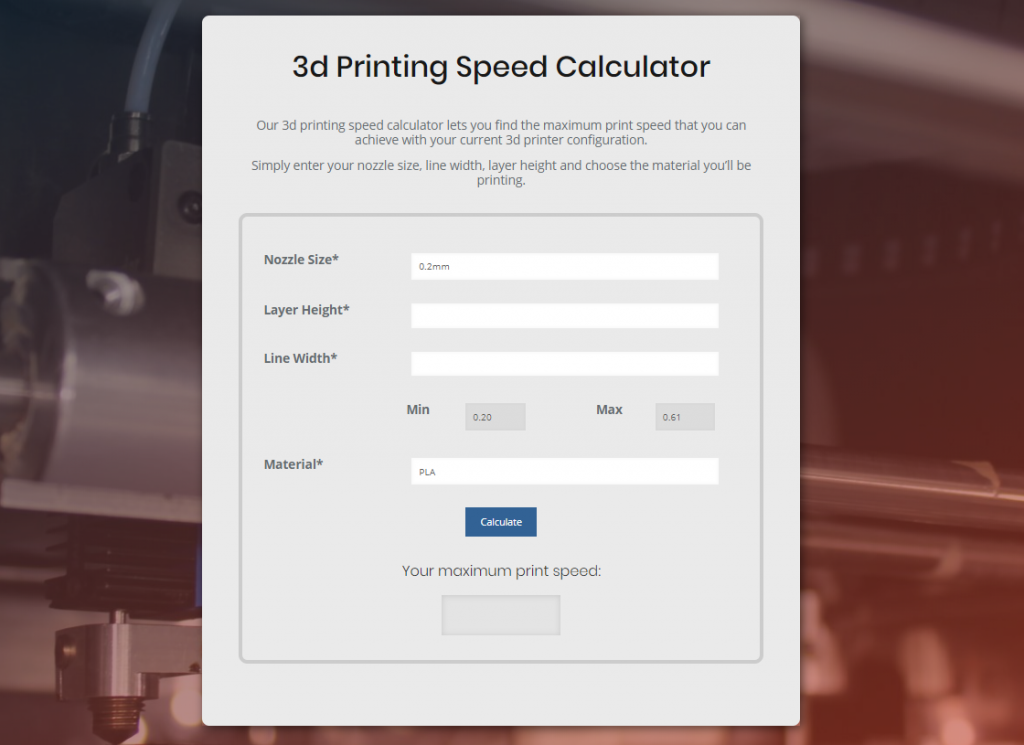

Now that you have a safe maximum flow rate calculated you can convert this back into a safe max speed for your 3D Printer. Ad Snapmaker Artisan 3-in-1 3D Printer is Coming in August 2022. Ad Streamline Desktop 3D Printing for Faster More Reliable Prints With High Accuracy.

To calculate the maximum flow rate we still need the diameter of your filament measure your filament at various points and calculate the average filament diameter. Alternatively please have a look at our affiliate links in the 3D Printing Deals and Coupons section. Use the calculator below to find out your safe maximum flow rate.

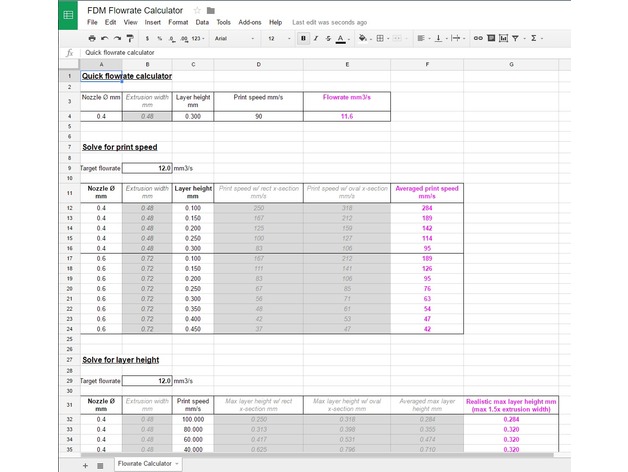

Lets assume that we have a maximum flow rate of 1386 mm³ and we want to print with a layer height of 02 mm and a layer width of 048 mm. Run out any remaining filament in the printers hotend. Thus the need for calibrating the filament flow rate.

To do this you need to calculate the surface area that. To use this calculator print a 20mm x 20mm x 20mm cube in vase mode and then measure the top 5 layers with your caliper. Naturally for many instances this is either too much or on the odd occasion too little.

If you cant access the value using the control interface dont worry. If the walls are thinner than 04mm the flow rate needs to. With a 04mm nozzle and a flow rate of 1 or 100 the thickness of a single wall should be 04mm.

Modify the flow rate to 90. Consequentially dimensional accuracy and line widths all go out of the window as there is no benchmark to calculate from. Use the calculator below to find out your safe maximum flow rate.

Artisan is fully improved in printing speed precision. Generally speaking the lower the viscosity of the material the higher the possible flow rate. Current Micro Steps Rate.

Now from within the 3D slicer set bottom layers to 1. New Micro Step Rate. A extrusion width identified in Step 52 b layer height2 c print speed.

How to calculate the correct flow rate with my flow rate calculator haha Close. Deliver Maximum Innovations By Making More Reliable Professional Educational Prints. Obtained the new flow rate 90 only remains to modify the parameter in the 3D lamination software that is used in our case the Cura 3D.

Now we can use this formula. Flow compensation is used to compensate for the expansion of the filament being pressed against the layer underneath. Hence by default 3D printing slicers set the flow rate to 10 or 100.

In a nutshell the feed rate value controls the overall speed of the printer whereas the flow rate value is responsible for the amount of plastic that comes out of the extruder. Lets assume that the max. How To Calibrate 3D Printer Flow Rate.

Max flow rate 10 pi 1715 2 2 10 314 175 2 175 2 2405 mm³ s. Recommended maximum speed maximum flow rate layer height extrusion width to calculate the maximum printing speed. The value there is the E-stepsmm.

Retrieve the previous E-steps settings from the 3D printer. If you find our articles helpful and would like to help support the Make N Print website please visit the support us page for more information. If we know the maximum flow rate of the hot end we can use this formula.

New Steps Per mm. Explore the Smarter and Faster 3D Printer Shop Latest From Anycubic Store. Calculate the maximum flow rate.

On a related note most materials used in FDM 3D printing become less viscous the. While modifying the feed rate will directly impact how quickly the motors of your 3D printer and as a result the axes including the printhead move adjusting the. Use this calculator correct for the expansion of the filament by adjusting the flow rate.

Max flow rate Max extrusions speed pi filament diameter 2 2. Remember to reset. R3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

And re-print the cube to verify that the measurements obtained with the new flow rate are correct. Calibrating the flow rate will involve printing a test cube and measuring its walls to identify the actual flow rate compared to the flow rate value. Measuring the calibration cube.

Volumetric flow rate is filament and temperature-dependent.

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Flow Rate Calibration Guide 3dmaker Engineering

Volumetric Flow Rate Calculator E3d Help Centre

Calibration Of The Flow Rate Extrusion Multiplier Of Our 3d Printers Just One Important Step Youtube

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Calculating Flow Rate For Your 3d Slicer Desiquintans Com

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

3d Printer Flow Rate Calibration The Easy Way Youtube

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

Nozzle And Venturi Nozzle Flow Calculator

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

Extrusion Flowrate Calculator By Luckypants Thingiverse

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print